Powder packaging machine manufacturer:

Sometimes we find that the filling volume of the powder packaging machine is inaccurate. What should we do at this time?

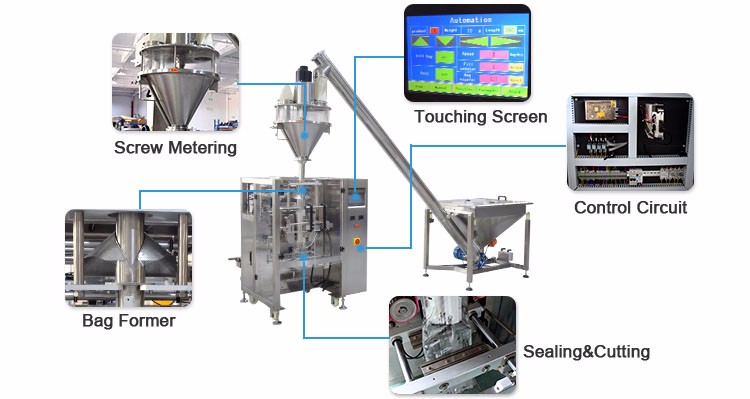

1. The relationship between the packaging accuracy of the powder packaging machine and the screw:

The powder packaging machine, especially for the small dose powder packaging machine, that is, the packaging specification is in the range of 5-5000 grams. The conventional feeding method is screw feeding, which is still the measurement method, and there is no instant weighing. Screw blanking is a volume measurement method, and the consistency of the volume of each pitch is the basic condition that determines the measurement accuracy of the powder packaging machine. Of course, the pitch, outer diameter, bottom diameter, and shape of the helical blade all have an impact on the packaging accuracy and speed.

2. The relationship between the packaging accuracy of the powder packaging machine and the

outer diameter of the spiral:

The packaging accuracy of the powder packaging machine has a very direct relationship with the outer diameter of the spiral, and the premise of the relationship with the pitch is that the outer diameter of the spiral has been determined before the comparison. Generally speaking, when selecting and matching the metering screw, the powder packaging machine is generally determined according to the size of the packaging specification, and the specific gravity of the material will be appropriately adjusted.

For example, our small-dose packaging machine usually chooses a screw with a diameter of 38 mm when packing 100 grams of peppers, but if the packaging is glucose with a higher bulk density, it is also 100 grams, so a screw with a diameter of 32 mm is used, that is to say The larger the packaging specification, the larger the outer diameter of the selected spiral, which can not only ensure the packaging speed, but also ensure the measurement accuracy;

3. The relationship between packaging accuracy and pitch of powder packaging machine:

What is the packaging accuracy and pitch of powder packaging machine? Here we can give an example to illustrate. For example, when packing 50 grams of cumin powder, our seasoning packaging machine uses a screw with an outer diameter of φ30 mm. The pitch we choose is 22 mm. The accuracy rate of 0.5 grams is over 80%, and the accuracy rate of 1 gram is over 98%. However, we have seen that peers use φ30mm outer diameter screw at customers. What will happen if the screw pitch exceeds 50mm? The cutting speed is very fast, and the measurement accuracy is about 3 grams.

The industry standard QB/T2501-2000 requires X(1) class weighing instruments with packaging size ≤ 50g, the allowable deviation is 6.3%, and it also meets the X standard. But for customers, packaging accuracy is directly related to product cost, which is better or worse.

Previous: None

Copyright © CoreTamp All Rights Reserved | Sitemap | Powered by