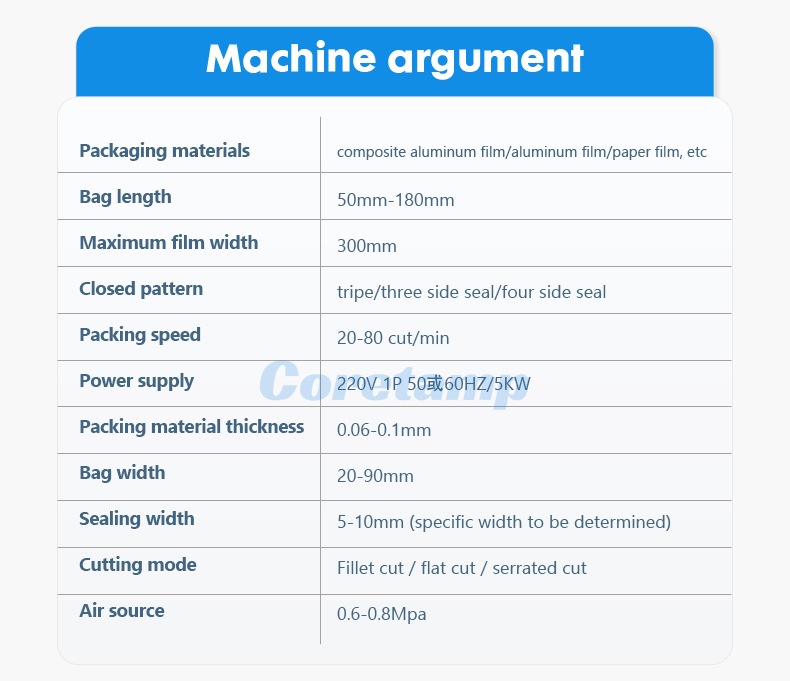

The liquid (paste) filling system is a high-precision gear pump quantitative filling device refined by CNC SUS316L stainless steel material, which has high precision, strong versatility, and is suitable for high-viscosity (pet food) materials.It is equipped with a general cleaning device as standard, but it can also be combined with a CIP cleaning system.

Easier maintenance

All parts in contact with the packaged material can be quickly disassembled and installed.

1.Efficient anti-fingerprint: the device is easy to clean.

2.System configuration: programmable bus system + bus servo, fast response and more accurate.

3.Color mark control: The color sensor is used to grab the color punctuation points of the packaging film to ensure the integrity of the pattern.

4.Applicable to digital factory: In response to the requirements of Industry 4.0 trend, it can be connected to SCADA and MES systems.

5.12 commonly used operation languages: simple operation, with equipment fault prompt, self-diagnosis function.

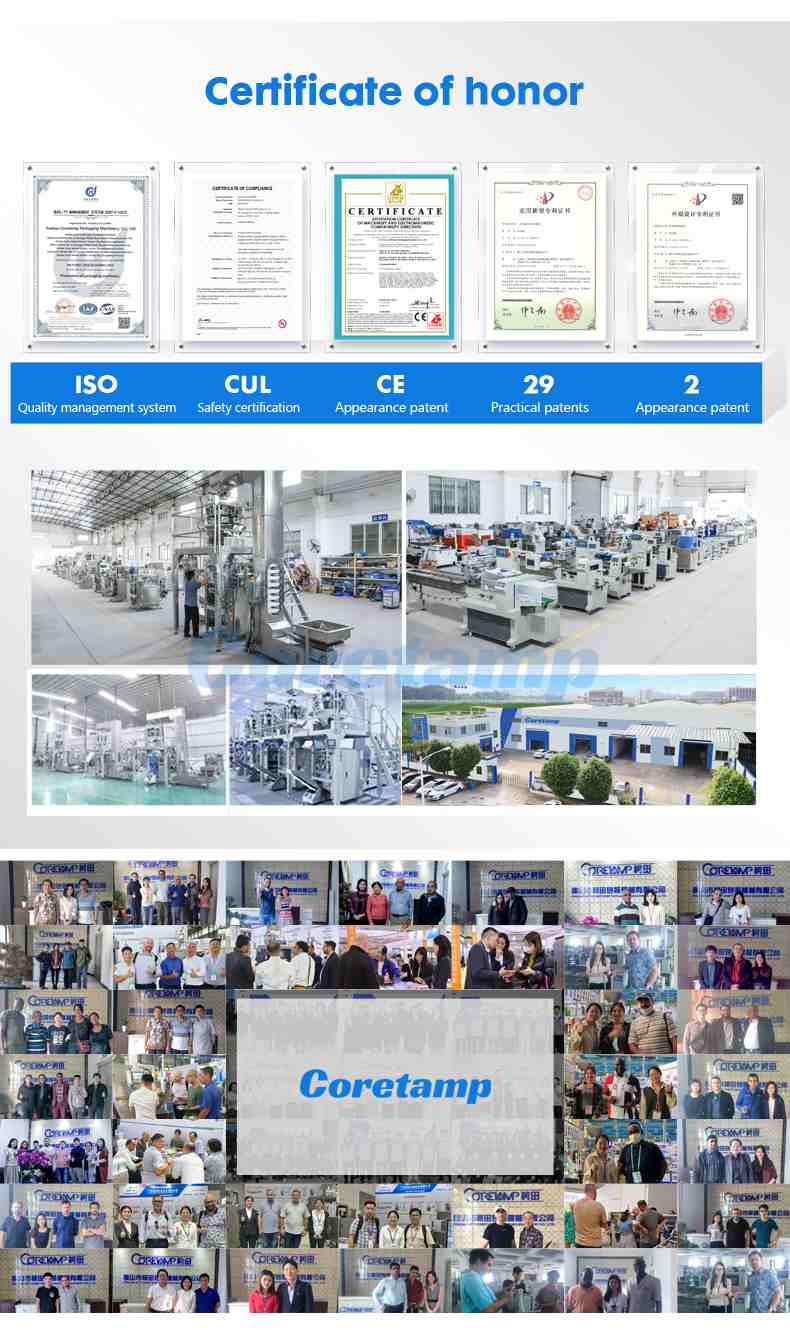

6.Safety & Certification: Comply with GMP production standards, the whole machine is CE certified, and the electrical configuration is CUL certified.

7.Food-grade stainless steel: The whole machine is made of SUS304 stainless steel, and the part in contact with the material is made of SUS316.

8.Temperature control mode: Bus type temperature module and independent temperature control, temperature accuracy control within ±0.1 degrees,Temperature display and setting are operated on the touch screen.

9.Automatic identification system for film breakage and film shortage: automatic alarm shutdown, film roll correction and docking device.

Copyright © CoreTamp All Rights Reserved | Sitemap | Powered by